4.9 1890+ Google Reviews

Flashing isn’t a word most people associate with roofs. Instead, most people think of police lights or Bourbon Street during Mardis Gras. However, it is an essential part of your roof that stops leaks. So, what is roof flashing?

Roof flashing is any waterproof material installed in vulnerable areas of the roofing system to create a watertight seal.

In layperson's terms, it's installed at potential leak spots to stop leaks.

For example, picture a skylight opening on the roof. The space between the skylight and the roof is a leak point. However, with head flashing at the top, step flashing at the sides, and apron flashing, it won't leak.

Roofers usually make it from sheet metal such as copper, aluminum, and galvanized steel. However, many different materials are available today, such as rubber, vinyl, and other plastics. Essentially, any waterproof thin material is suitable.

Yes, building codes require roof flashing. However, since flashing application isn't always the same, code requirements are minimal and general. Specifically, the 2021 IRC (International Residential Code) states:

"R903.2 Flashing.

Flashings shall be installed in a manner that prevents moisture from entering the wall and roof through joints in copings, through moisture-permeable materials, and at intersections with parapet walls and other penetrations through the roof plane."

And as far as specific locations, the 2021 IRC goes on to say:

"R903.2.1 Locations.

Flashings shall be installed at wall and roof intersections, wherever there is a change in roof slope or direction, and around roof openings. In addition, flashing shall be installed to divert the water away from where the eave of a sloped roof intersects a vertical sidewall."

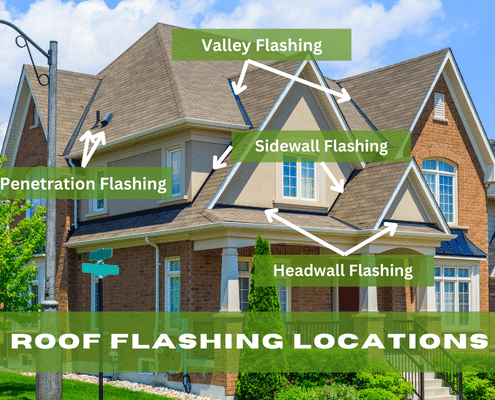

There are many different types of roof flashing. Keep in mind that chimney flashing, skylight flashing, and other specific types of flashing consist of the following flashing types.

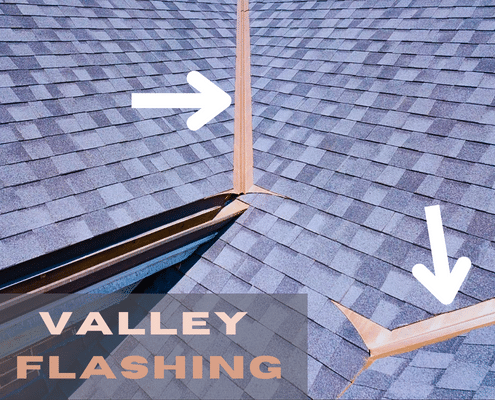

A roof valley is the v-shaped structure formed when two different roof slopes meet at an angle. For example, look at the photo below with many roof valleys.

Since two roof surfaces drain water into the valley, it is prone to leaking. Plus, valleys are prone to clogging from leaves and other debris.

With this in mind, special attention to valley flashing by a professional roofer is crucial to prevent water penetration (leaks).

The roofing material and installation method determine the correct flashing material. However, for the most part, valleys require 24-36 inch wide flashing. As a result, any water that makes its way under the roof covering will not leak into the house.

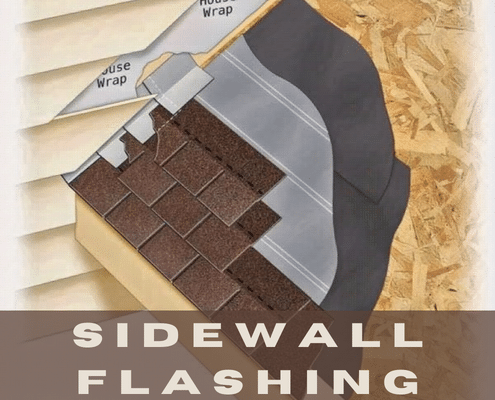

In roofing, a sidewall is a vertical wall that intersects with the sloping slide (called the rake edge) of a roof. For example, the intersection between the side of a chimney and the roof is a sidewall.

Two types of flashing work together in these areas to stop leaks.

First, a roofer installs step flashing between the shingles. This involves a series of individual pieces of flashing installed between each shingle and up against the wall. However, this still allows water infiltration.

Next, the roofer installs counter flashing (also called cap flashing) over the step flashing and seals it against the wall. Counter flashing is simply a long piece of flashing installed over other flashings.

Sometimes the home’s siding will act as the counter flashing. For example, vinyl siding installed over the step flashing acts as counter flashing.

Additionally, kickout flashing installed at the base of the flashing directs water away from the wall.

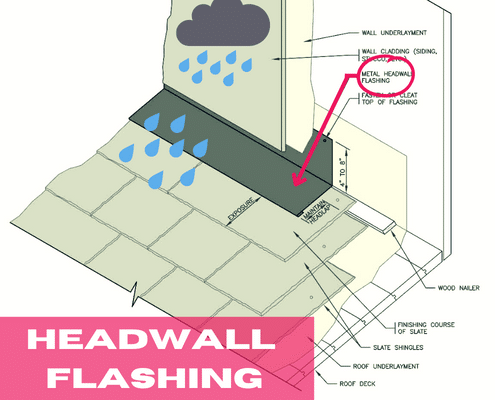

Similarly, a headwall is a vertical wall that intersects with a horizontal roof surface. For example, the wall above a porch roof is a headwall.

Unlike step flashing, headwall flashing is a long piece of flashing. Installed over shingles and against the wall, it covers the gap between them to stop leaks.

And like step flashing, counter flashing installed over the headwall flashing creates a leakproof joint.

Almost all roofs have at least one hole, but typically more than one. This is because building codes require at least one plumbing vent pipe to extend above the roof. Unless the plumbing vent runs along an exterior wall, which is rare, it needs to penetrate the roof’s surface.

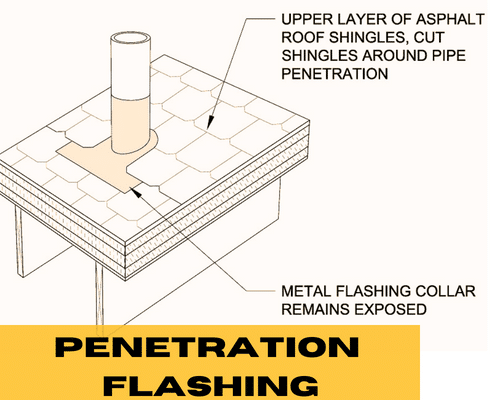

There are special flashings for vent pipes and other roof penetrations. They are prefabricated and typically made from plastic or stainless steel and a rubber seal. Plus, different roof materials require different types of penetration flashing.

On a shingle roof, shingles overlap the high side, and sides of the flashing. To direct water on top of the shingles and down the roof, the bottom is left exposed.

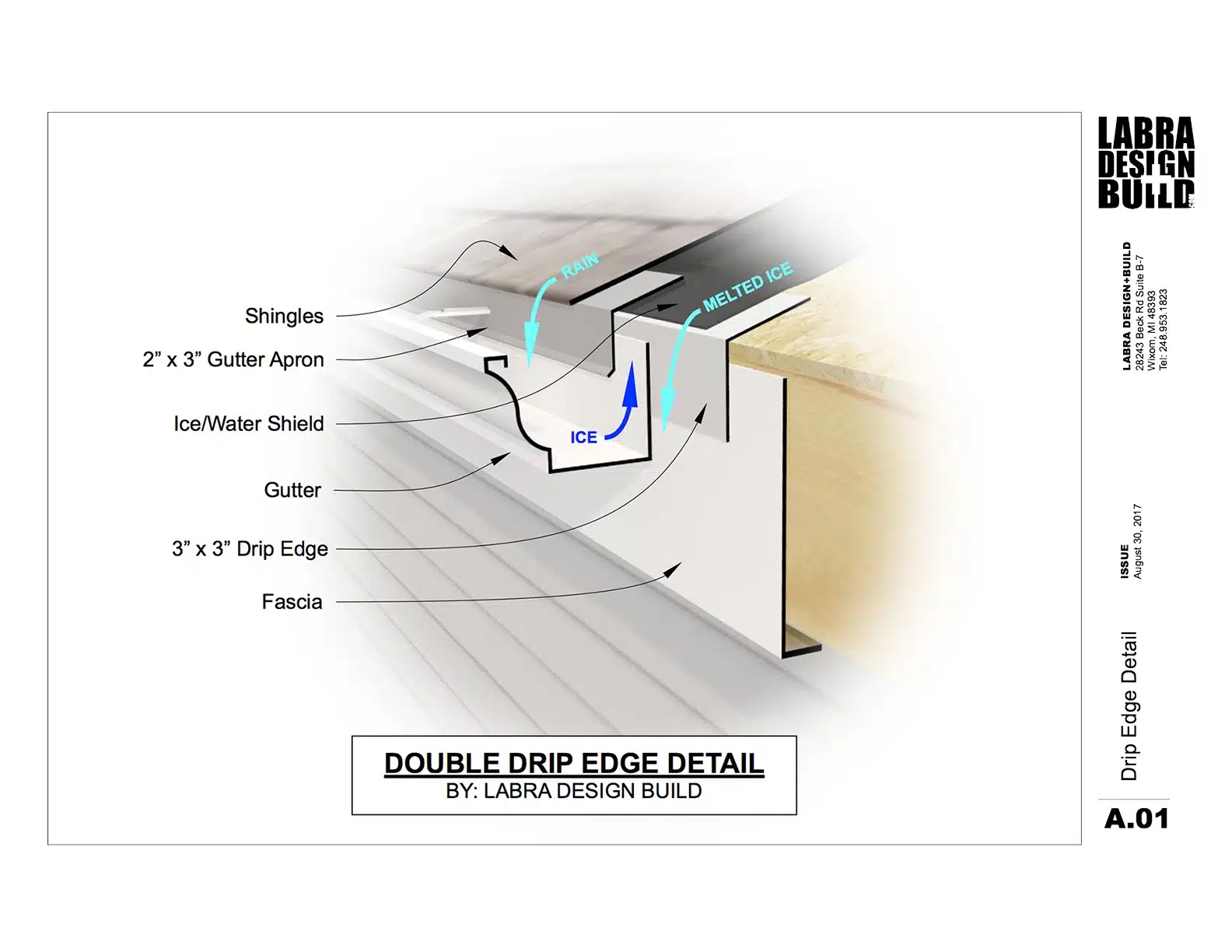

Drip edge flashing directs water draining off the roof into the gutters. Otherwise, water tension causes the water to follow the shingle back to the roof deck.

All of the roof edges need drip edge flashing. At the eaves, a roofer installs the drip edge flashing under the roof underlayment. Conversely, it’s installed over the roof underlayment at the rake edge.

It depends on the type of flashing. For example, step flashing is rarely visible, but penetration flashing is almost always visible. However, an experienced roofer can hide all flashing for a cleaner aesthetic.

It depends on the type of flashing. For example, headwall flashing goes over the shingles, but valley flashing goes under the shingles. Check out the images above for more detail.

Home inspectors are not required to get on roofs, and a lot of flashing is not visible. However, many inspectors do get on roofs and inspect flashing. So, make sure you ask your inspector and check your inspection report to determine if the flashing was inspected.

Roof flashing stops leaks and water damage. Ultimately, it’s a crucial component of your roof system, and poorly installed or missing flashing causes many leaks. Likewise, proper flashing is the best way to protect your roof structure from leaks and moisture damage..